BOS smart battery management

The heart of the hybrid system explained by experts

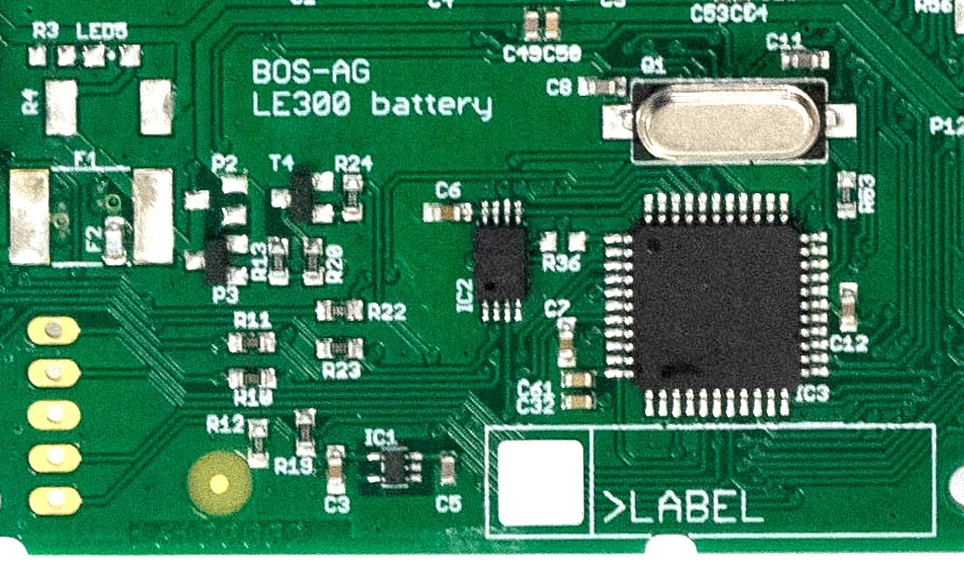

We use our many years of expertise to develop powerful and reliable battery systems. Our LE300 is the first lithium battery that can be used in hybrid with lead acid systems, without any changes to the charge controller. The patented hybrid technology brings a number of never seen advantages. Therefore, the LE300s integrated high performance Battery Management System uses intelligent algorithms to optimize the use of capacity and charging cycles of the system in the long run.

Lithium for cycling and Lead-acid for basic load

The principle of the hybrid system considers the low-cost lead-acid battery as a long-term storage and backup, while the lithium battery handles the daily cycles. Through this combination it is possible to counteract typical shortcomings of the lead technology with the lithium battery. For this purpose, the BOS smart battery management system monitors the applied voltages and the behavior of the lead-acid battery. It adapts the behavior of the lithium battery to achieve an improved performance and lifetime of the overall system.

In the charging process, the charging of the lead-acid battery is prioritized. This ensures that the lead-acid battery remains fully charged and therefore never suffers from sulphation while the LE300 provides power for the loads. This eliminates the most common problem that leads to a replacement of the lead-acid batteries after only one to three years, when in theory they are considered to have a life span of 8 to 10 years. The LE300 smart battery management system helps to use the full potential with this procedure.

During the charging process, the lead-acid battery reaches a constant voltage charge and the charge current is reduced. The smart battery system detects this and the LE300 absorbs the available energy that is not taken by the lead acid battery. As a result, both batteries are charged at maximum available charge current, until they are full. Especially with solar power, the full potential of the generated energy can be utilized in every moment, while the lead acid battery gets many charging hours to reach 100% every day.

When not using a lead acid battery during winter, it must be connected to a charger. Also for this use case, the LE300 lithium battery keeps the lead-acid battery fully charged for several months, with a voltage around 13V that allows to maintain the lead acid battery healthy, without being connected to a landline.

In daily use, the lithium battery powers the loads. This way, the lead acid battery is kept full and the lithium battery makes the daily cycles. The battery management system, however, manages to cover large load peaks by both batteries in parallel. Therefore, the BOS hybrid technology can supply even the largest load peaks, without any limits or unexpected system shutdowns. In contrast, with pure lithium systems, huge load peaks can be limited or cause issues once the BMS tries to protect the battery cells, leading to error messages or an unexpected system shutdown.

For extended power usage, or on cloudy days when no solar energy is generated, the lead-acid battery with its cheap large storage capacity remains as a backup. This way, both batteries can do what they are designed for: A downsized lithium battery runs the daily cycles, and a lead acid remains as a backup, ready to jump in when larger amounts of energy are needed.

Used lead acid batteries in existing systems, can still be used and do not have to be replaced. Any capacity can be added to existing batteries. This way the lead-acid battery can be used in a second life, and won’t go to waste. An important step to meet the responsibility towards our planet and the environment.

Safety is always first

Engineered in Germany, the BOS LE300 has an inbuilt Battery Management System, with has several effective protection mechanisms to prevent risks or damages by any external influence. Thanks to the simple plug and play approach with the multiple protections built in, you don’t need to be a battery expert to use the LE300 safely. The smart battery management system monitors the applied voltages and the behavior of the lead-acid battery, it adapts the behavior of the lithium battery to achieve an improved performance and lifetime of the overall system.

Each LE300 module has a built-in electronic protection mechanism against short circuits. In a redundant manner, each module is additionally equipped with its own 20-amp fuse, which protects the LE300 in the event of a short circuit with fully redundant protection features.

The LE300 has several temperature sensors that ensure that the lithium batteries are not operated at harmful temperatures. The integrated cell heating allows to charge the battery in extreme temperatures. In case extremely high or low temperatures are detected, the LE300 will reduce its maximum power, and outside the operation range it will shut down to protect the health of the lithium cells.

The protection against wrong polarity connection ensures that the LE300 will not be damaged if the plus and minus pole is accidentally reversed. The LE300 will also check for appropriate lead acid battery voltage, so there is no voltage on the LE300 plug until appropriate connection is established.

Overvoltage protection elements are installed as important components that ensure that dangerous overvoltages are grounded in fractions of a second, preventing the destructive high voltage from reaching the LE300 battery cells and BMS electronics.

Overcurrent protection in the LE is a protective function in the LE300 BMS, to limit the current flow, which protects the circuit and enables to power big loads from LE300 and lead acid battery in parallel, working together for ideal performance.

The overcharge protection circuit of the BMS protects the battery from overcharging. When a battery is charged, the voltage between the battery’s anode and cathode rises. When fully charged, the terminal voltage reaches a peak value indicating a full charge. Charging a battery cell beyond its full value will result in permanent or temporary damage to the battery, so the BMS tracks every single cell voltage, and protects the battery effectively.

The BMS protects against deep discharge of the lithium cells. It shuts down before one battery cellit discharges completely, so there is always a small amount of energy saved to keep the electronics active. A highly efficient sleep mode will allow to recognize charging voltages. After some weeks in completely empty mode the LE300 will protect itself with a deep sleep mode, that consumes almost no energy but requires to press the button to wake up the unit for the next charging.

We value the integration of all possible safety features. The in-house research and development department in Germany develops and tests all components in detail. This is the key to guaranteeing higher quality and safety than purely imported products tend to bring. Experience the outstanding performance and quality of BOS products for yourself.